Introduction

In the Middle East’s extreme climate, efficient cooling is the backbone of building performance. With ambient temperatures regularly exceeding 45 °C and humidity levels straining HVAC systems, poorly designed chiller yards and cooling towers can lead to energy waste, recirculation, and reduced plant efficiency. Computational Fluid Dynamics (CFD) provides a powerful way to visualise airflow, predict thermal interactions, and optimise designs before construction. This article explores how chiller yard CFD and cooling tower CFD analysis transform the performance and reliability of cooling systems across the region.

Understanding Chiller Yard Challenges

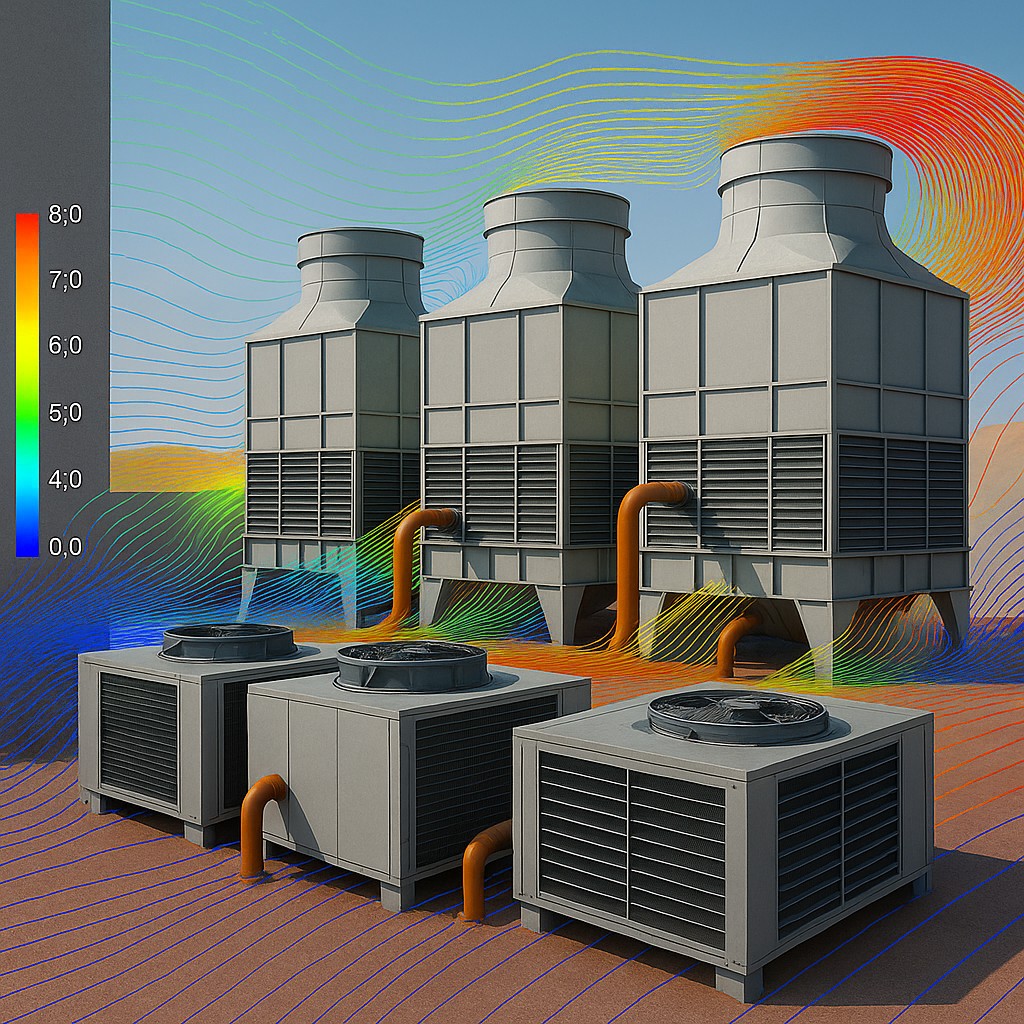

A chiller yard’s effectiveness depends on unobstructed airflow. When exhaust air from cooling towers or chillers re-enters the air intakes — a phenomenon called air recirculation — the system must work harder to achieve the same cooling load. High surrounding walls, poorly placed equipment, or unfavourable wind directions amplify this effect, especially in dense urban areas like Dubai or Riyadh.

Through CFD consultancy UAE studies, engineers can assess these factors in 3D, identifying recirculation zones, temperature rises, and stagnation regions. This data allows MEP teams to adjust tower spacing, wall openings, and fan orientation to achieve better performance with minimal energy penalties.

Cooling Tower Analysis and Optimisation

Cooling tower CFD analysis enables simulation of thermal plume dispersion, humidity patterns, and exhaust drift. By visualising airflow around the cooling towers, designers can determine whether hot, humid air will linger near air intakes or rise and dissipate naturally. CFD also supports decisions about the height of parapets, tower fan speeds, and louvers to enhance air rejection and avoid short-circuiting.

When combined with climatic data from the UAE and KSA, CFD provides an accurate prediction of seasonal behaviour — showing how cooling performance changes between peak summer and milder winter months. This insight is invaluable for facility managers aiming for long-term energy efficiency and compliance with Estidama or LEED sustainability targets.

The Role of HVAC CFD Modelling in System Design

HVAC designers often rely on CFD to complement traditional load calculations. HVAC CFD modelling can simulate wind velocities, temperature contours, and turbulence intensities, helping engineers validate whether proposed layouts meet performance objectives. For example, CFD may reveal that a small shift in cooling-tower alignment or the inclusion of a vertical baffle reduces recirculation by 30 percent — saving thousands of kilowatt-hours annually.

Cooling System Optimisation Through Simulation

In retrofit projects, chiller yard analysis helps identify underperforming zones and supports decisions for remedial measures such as additional extract fans, louvres, or deflectors. In new builds, CFD enables early-stage design optimisation, avoiding costly changes during construction.

At Lava Consultants, our engineering team uses CFD tools to deliver precise, performance-based design recommendations for developers, consultants, and contractors across the UAE, KSA, and Qatar.

Conclusion

CFD consultancy UAE services are no longer optional — they are essential for cooling-system optimisation in the Middle East. Through chiller yard CFD and cooling tower analysis, designers can ensure efficient airflow, lower operating costs, and extend equipment life.

Lava Consultants, Dubai specialises in HVAC CFD modelling and performance-based engineering. Contact us at www.lavaconsultants.com to discuss how advanced CFD simulation can enhance your next cooling-system project.