At LAVA Consultants, we use Computational Fluid Dynamics (CFD) to analyse and optimise airflow in chiller yards, helping designers and facility operators improve system efficiency, reduce energy consumption, and extend equipment life.

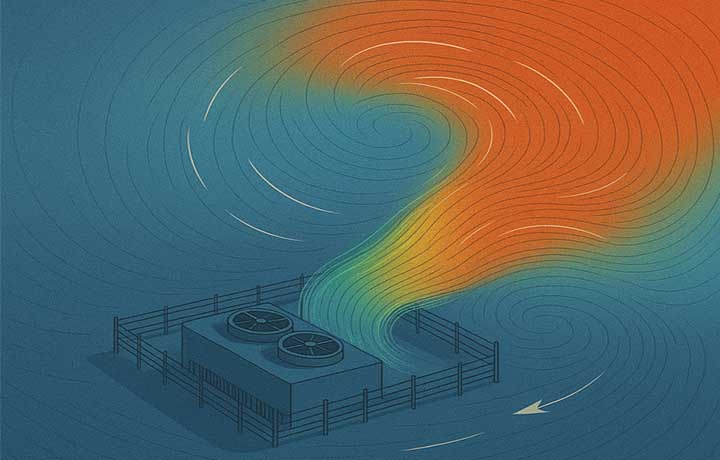

Chiller Yard CFD plays a vital role in improving the reliability and efficiency of cooling systems in hot climates such as the UAE, Saudi Arabia, and Qatar. By applying Computational Fluid Dynamics (CFD) techniques, engineers can simulate airflow, heat rejection, and temperature distribution within chiller yards. This level of chiller yard analysis provides valuable insight into potential performance issues such as hot air recirculation, stagnant airflow zones, and inefficiencies in cooling tower operation. Identifying these challenges early helps design teams optimise layout, equipment placement, and barrier strategies to maintain stable cooling performance under extreme conditions.

Cooling tower analysis is a critical component of Chiller Yard CFD, as cooling towers often determine the overall efficiency of HVAC and district cooling systems. Through detailed CFD modelling, airflow behaviour and plume dispersion can be visualised, allowing engineers to identify risks of recirculation and reduced heat rejection. Cooling tower CFD studies also support compliance with sustainability goals by reducing energy consumption and operational costs, while extending equipment life through optimised performance.

In regions like Dubai, Abu Dhabi, and Doha, where high ambient temperatures put significant stress on cooling systems, Chiller Yard CFD analysis offers a proactive approach to performance optimisation. Developers, consultants, and contractors rely on cooling tower analysis and chiller yard CFD simulations to achieve cost savings, improve energy efficiency, and secure approvals from local authorities. At Lava Consultants, we specialise in delivering accurate, project-specific chiller yard CFD and cooling tower CFD studies that give clients actionable recommendations and peace of mind that their cooling infrastructure will perform reliably in demanding climates.

Inadequate airflow management within chiller yards can lead to hot air recirculation, where exhaust air expelled from one chiller is drawn into the intake of another. This raises the inlet air temperature, reducing the capacity to reject heat and reducing the efficiency of the chiller.

This can result in:

By simulating airflow patterns and temperature distribution using CFD, issues related to air recirculation can be identified.

A typical CFD study of a chiller yard includes the following steps:

Step 1: 3D Modelling of the Yard

A 3D model of the yard will be created incorporating chiller units, their intake and exhaust configurations, nearby buildings and any other obstructions that may affect the surrounding airflow.

Step 2: Defining Environmental Conditions

Simulations will be run under multiple wind speeds to understand airflow behaviour during both typical and adverse weather conditions.

Step 3: Simulation of Airflow and Temperature

CFD tools will predict how air moves through the space to identify where it may stagnate or recirculate, and how temperatures are affected across the yard.

Step 4: Analysis and Recommendations

Key outputs of the simulation include:

Depending on the findings, design improvements may include increasing spacing between units or installing vertical barriers. These interventions can potentially reduce energy consumption.

Chiller yard CFD analysis is valuable for:

Whether for new design verification or retrofit upgrades, CFD helps ensure that HVAC systems perform as intended in real-world conditions.

Lava Consultants offers expert CFD solutions tailored to the built environment. If you’re facing performance issues with your cooling system reach out to us for a consultation.

Chiller Yard CFD uses Computational Fluid Dynamics to simulate airflow and temperature in chiller yards, ensuring efficient cooling system performance.

Chiller Yard CFD analysis identifies hot air recirculation and airflow inefficiencies, helping prevent reduced cooling capacity, high energy use, and equipment wear.

Cooling tower analysis predicts airflow and temperature patterns, allowing designers to optimise layout, reduce recirculation, and improve heat rejection efficiency.

It includes 3D modelling of the yard, defining environmental conditions, simulating airflow and temperature, and providing recommendations to enhance performance.

CFD can suggest spacing adjustments, installation of vertical barriers, and other interventions to reduce recirculation, improve cooling, and lower energy consumption.

Office towers, commercial complexes, hospitals, universities, data centres, shopping malls, industrial facilities, and manufacturing plants benefit from Chiller Yard CFD analysis.

Lava Consultants offers expert Chiller Yard CFD analysis in Dubai and Melbourne, providing detailed airflow simulations, actionable recommendations, and optimized cooling system performance.

© 2025 Lava Consultants. All rights reserved